March 6, 2020

Powerhouse team of female entrepreneurs changes the future of sensor technology

Last June, SAIT co-op student Nicole Calma landed a ticket to an event that would transform her future. She’d been identified as an emerging innovator on UCalgary’s Canada Excellence Research Chair in Materials Engineering for Unconventional Oil Reservoirs (CERC) team.

Her skills and dedication inside the lab, and eagerness and outgoing persona outside of the lab, made her an ideal candidate to attend the 2019 Energy New Venture Competition (ENV) – a single-day pitch competition dedicated to the advancement of emerging innovations for the energy sector.

Chance meeting has undeniable impacts

She didn’t know it at the time, but that pitch competition was the start of something big. Total Containment Inc. was pitching in the Concept stream at the competition. Although company CEO Larry Young didn’t walk away a winner, he left with valuable connections that proved winning first place wasn’t necessarily the biggest prize for him.

“Following my pitch, a young lady approached me, explaining she and her team had invented a cheap, rapidly deployable sensor that would enhance the pipeline leak containment system I developed,” says Young.

That person was Nicole Calma, and their meeting is a great example of how the marriage of academics and industry can lead to something bigger than both. “A challenge for my containment system was determining exactly where a leak would occur, but if we marry the two technologies together, the impacts are undeniable,” Young explains.

- Photo above: The SenSyn Inc. team, from left: Nicole Calma, Erin Gawron and Stephanie Kedzior. Photo by Adrian Shellard, for the University of Calgary

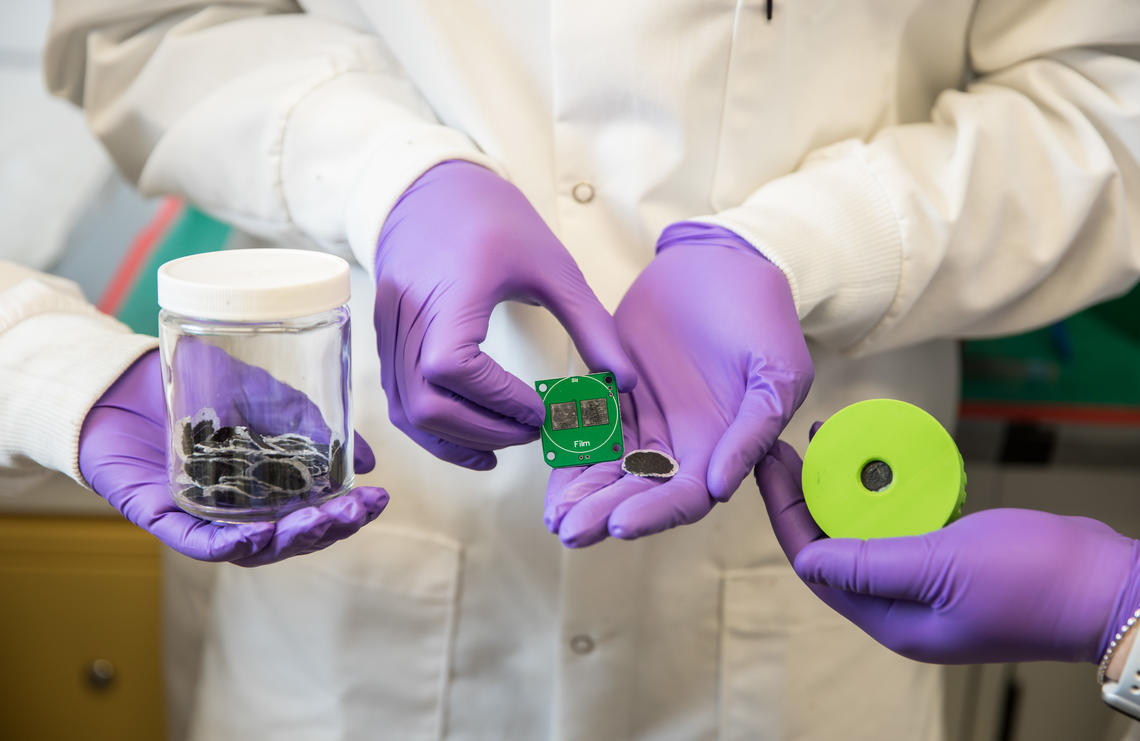

His company represents one of many potential applications for the leak detection sensor that was developed through determination and perseverance. The sensor was originally just a self-supported nanoparticle composite film made up of inexpensive polymer and conductive material, and researchers in the CERC lab were not entirely sure which potential application to pursue.

SenSyn Inc.’s patented composite film.

Adrian Shellard, for the University of Calgary

Supportive environment drives results

When postdoctoral scholars Erin Gawron and Stephanie Kedzior joined the CERC team, they had some ideas for the film, but at the time were uncertain if those ideas could be developed into practical solutions.

“Discoveries in the lab happen all the time,” says Gawron. “The real challenge lies in determining what you can do with those discoveries outside of the lab, and how you can scale them into practical real-world applications.”

Calma’s encounter with Young at ENV opened her mind to the possibility of a path for their technology outside of the lab. “When I met Larry, it provided me with motivation and incentive — the kick in the pants we needed — to really get our technology ready for commercialized use,” says Calma. Having a timeline meant rapid development would be needed inside the lab.

Campus network fuels discovery

While Gawron and Kedzior worked on fine-tuning the film, Calma got to work on creating the technology that would house the sensor when deployed. Without a background in engineering, Calma knew she would have to quickly develop a network on campus to teach her the skills she would need to create the housing device.

“Sometimes we would go weeks without seeing Nicole, because she would be elsewhere on campus networking, learning and making connections. When she returned, she always had amazing prototypes that we could test,” says Kedzior. “At the beginning, we knew we needed a co-op student to help us with this technology. We wanted someone who would be resourceful and could solve problems on their own, and that is exactly what we got from Nicole.”

Calma met with students from science and engineering to learn about different materials and techniques to help her build the sensor’s housing device. The Maker Multiplex at the Schulich School of Engineering became her most valuable outlet, providing her with tools and equipment to bring her ideas to life.

“I targeted first- and second-year students because they spoke in general terms which helped me understand, as I was trying to learn myself,” says Calma. “We leveraged every possible resource we had – campus resources, the CERC lab, family. We went into a stranger’s basement and even a bee farm to learn, so we could make sure this was successful.”

Showcasing technology leads to improvements

Calma gained additional exposure for the technology through opportunities led by the Office of the Vice-President (Research), including the Global Petroleum Show and the Society of Petroleum Engineers’ annual technical conference and exhibition.

“Having the opportunity to attend these events and showcase our technology, share our technology with such a diverse group of companies and experts, provided us with countless ideas to improve our product,” says Calma.

One of our biggest lessons through this whole experience has been the importance of making connections and learning.

The final sensor they developed is simple, cost-effective and can detect light oil in one second and dilbit in five seconds. The sensors are robust and can easily and efficiently integrate into new and existing infrastructure, saving time and money, all while protecting the environment.

CERC’s Discovery to Impact model

Dr. Steven Bryant, PhD, leads the CERC team and has created a successful model for discoveries made in the lab – a model he calls the Discovery to Impact Pipeline. “The University of Calgary is home to cutting-edge technology, equipment and brilliant minds. What we’ve done at CERC is create an ecosystem where all of those things come together,” says Bryant.

“We encourage innovation, curiosity and exploration at every level, and provide the means. And because we have a diverse set of backgrounds on the team, we are also alert to discoveries that have potential impact to industry and the community.”

Stephanie Kedzior can attest to the success of the model. “When I first started as a postdoc, I was focused on research fundamentals,” she says. “Dr. Bryant provided me with the opportunity to expand my skill set and shift my mindset to focus on discoveries that will make an impact. He provided us with an environment where we are encouraged to innovate and create.”

SenSyn’s leak detection sensor, including the patented composite film, sensor and housing device.

Adrian Shellard, for the University of Calgary

When Calma’s co-op came to an end and Gawron had to move away, CERC made sure the team had what they needed to keep working together, and at the end of 2019, SenSyn Inc. was born. “We are a strong team of women supporting women. We challenge each other, but also support each other to find solutions,” says Gawron. “We truly want the best for each other and are willing to go to great lengths to make sure each other succeeds.”

A bright future

The SenSyn Inc. team continues to develop their technology in the lab, fine-tuning it and expanding its applications. “We have heard from several key players in this space who are excited about this technology and the potential applications,” says Bryant. “The positive response is not only an indication of how beneficial this product is, but it’s also an indication of how this team’s hard work and dedication will provide impact.”

The team is hopeful the future of SenSyn Inc. will include detection technology for a multitude of hydrocarbons, the extraction of metals in aqueous environments and an application for converting CO2 into the feedstock for useful products. Although all of the founding members have multiple projects and competing priorities, they are excited to see where the future takes them.

And Larry Young also continues to make strides with Total Containment, recently completing two rounds of the CDL-Rockies Energy stream. “I look forward to our future relationship with the SenSyn team as we continue to develop our pipeline leak containment system.

“Detection is both important and expensive. Providing an inexpensive means of detection that also has the potential to provide leak location at this level of reduced cost is unheard of in the industry,” says Young. “This group of bright young women make me hopeful for the future of energy innovation in Alberta.”

If you would like to learn more about SenSyn Inc., CERC or would like to engage the team, please contact cerc@ucalgary.ca.